Eddy Current testing

Eddy Current Testing (ECT) is a precise and efficient non-destructive testing (NDT) method used to detect surface and near-surface defects in conductive materials. It is particularly effective for identifying cracks, corrosion, and material variations without the need for contact or surface preparation.

Del NDT Services

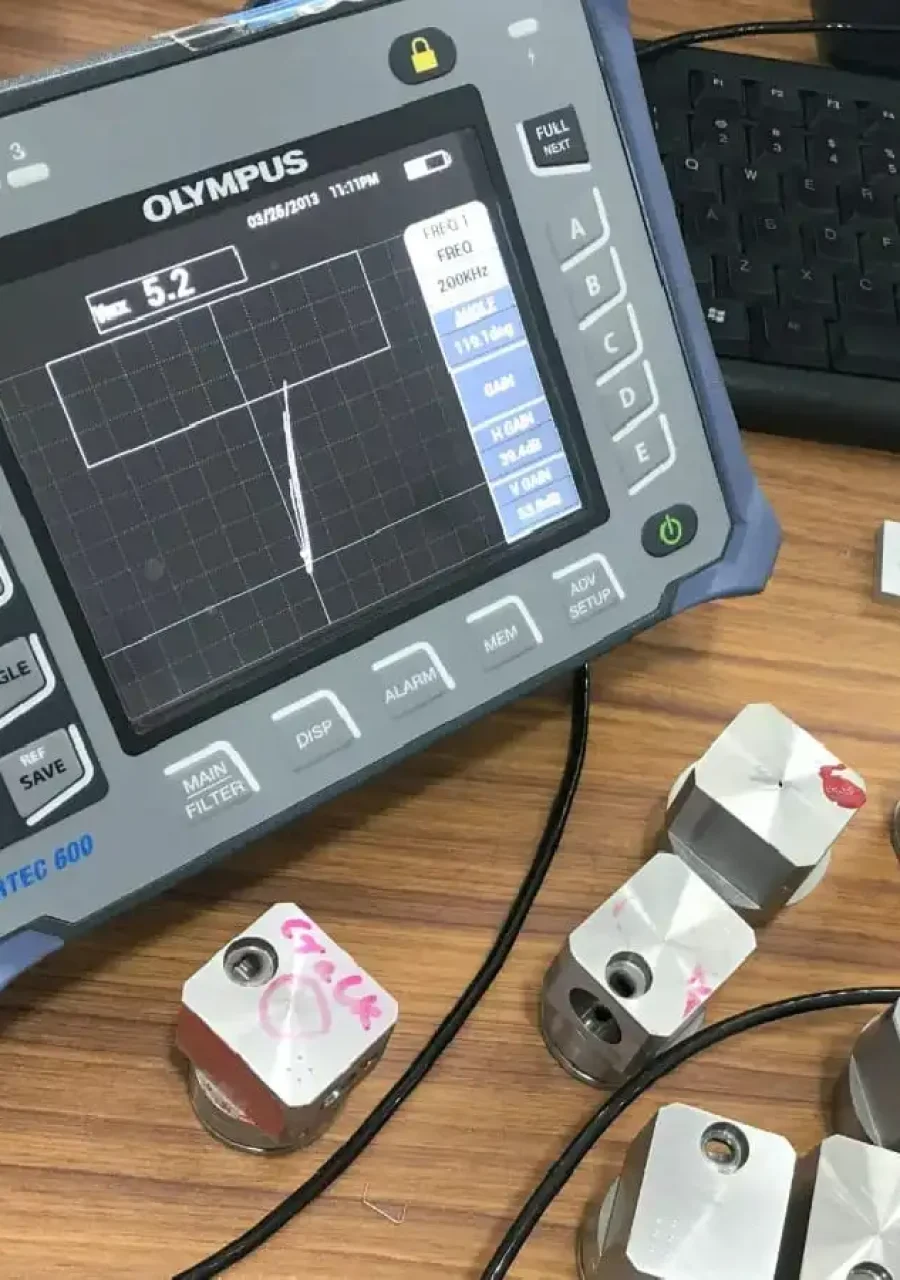

At Del NDT Services, our qualified technicians use advanced eddy current instruments to perform accurate inspections on a wide range of components and materials. The technique works by inducing electrical currents (eddy currents) into the test material using an alternating magnetic field. Changes in these currents reveal defects or inconsistencies in the material’s structure.

- Detects surface and near-surface cracks, pits, and corrosion

- Ideal for non-ferrous materials such as aluminium, copper, and stainless steel

- Quick inspection with immediate results

- No need for couplant or extensive surface preparation

- Portable and versatile for on-site testing

Applications

All inspections at Del NDT Services are conducted in accordance with relevant Australian and international standards (AS 2083, ASTM, ISO), ensuring accuracy, reliability, and full compliance with client and regulatory requirements.

- Weld and surface crack detection

- Tube and heat exchanger inspection

- Aircraft and aerospace component testing

- Corrosion mapping and conductivity measurement